"To each their own", "Different strokes for different folks"...

…different board construction for different waves (not quite so catchy, but hey).

But it’s true, the construction type of your board will impact the way you ride certain waves, plus a whole host of other variables too.

The two main construction types to choose from are PU and Epoxy, but which is better, and which should you choose?

Let’s take a closer look.

SUMMARY: Epoxy surfboards are stronger, lighter, and more buoyant, helping them to glide over the waters surface - great for small waves.

PU surfboards have more flex, cut through the water, and are preferred for high performance surfing in more powerful waves.

LEARN ONLINE:

ALL COURSES, ALL LESSONS & SESSIONS $9P/M [BILLED ANNUALLY]

CONSTRUCTION DIFFERENCES (WHAT'S UNDER THE HOOD)

Ok, so there’s a bunch of confusion over the terminology between PU and Epoxy boards, so let’s just set the record straight on that first:

PU (POLYURETHANE)

PU or Polyurethane refers to the material construction of the surfboard foam blank.

PU blanks are glassed using fibreglass cloth, and Polyester resin.

EPOXY

Epoxy surfboards are made from EPS foam (Expanded Polystyrene) blanks.

These EPS foam blanks are glassed using fibreglass cloth, and Epoxy resin.

Q. What happens if you use Polyester resin on an EPS blank?

A. Polyester resin is not compatible with EPS foam. If applied, it initiates a chemical reaction, dissolving the foam - essentially melting it upon impact.

SO... WHAT’S THE DIFFERENCE?

Looks the same, smells the same, but don’t work the same.

Yup, there are some big differences between PU & Epoxy surfboards:

STRENGTH

FLEXIBILITY

WEIGHT

FEEL

ENVIRONMENTAL IMPACT

Q. Stringer vs no Stringer?

A. Stringerless surfboards have become synonymous with Epoxy/EPS boards, however, they're available in PU too.

Contrary to popular opinion, the stringer provides little to no additional strength, with all strength coming from the resin and fibreglass cloth combinations.

OTHER THINGS TO CONSIDER

Sure, there are some differences in performance between the different construction types, but that's not all:

PRICE

A quick internet search will show you that there's a distinct difference in price between Epoxy and PU, but why is that?

Put simply, they're more costly and are time consuming to produce:

So you'll need to bare in mind the price differential when choosing your next board.

SURF VIDEO ANALYSIS [REMOTE]

REPAIR

You're going to ding your board at some point, and that's going to mean repairs, and repairing an Epoxy is way more of a headache than fixing a PU.

First up, EPS blanks hate any water, so when you get a ding you've really got to get that thing fixed quickly - so no shoving wax in that thing.

Secondly, the repair process is more complex, as the resin is harder to work with. Whereas with a PU you can get away with bogging it with a bit of Solarez, with Epoxy it can be a bit more complex.

Sure, you can get away with botch job for a bit, but the fix job can shrink over time opening the ding back up to water penetration - so unless you're an expert, it's probably better to get it fixed by a professional which ain't cheap.

WHICH WAVES SUIT WHICH TYPE?

So we can see that PU and Epoxy surfboards have quite different characteristics, but how does that effect them in the waves?

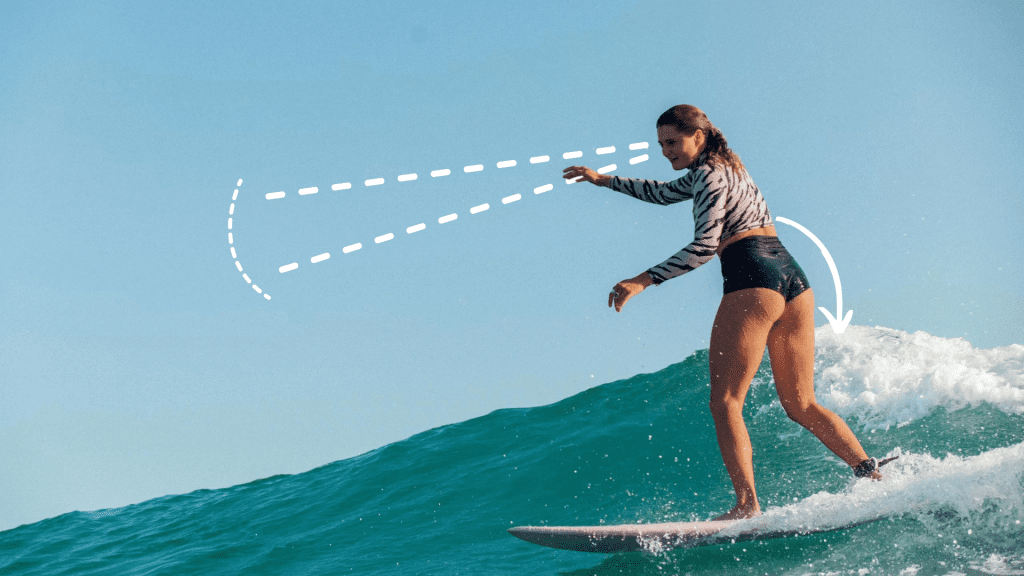

SMALL WAVES: 1-2FT

In small waves, generating and maintaining speed is a big deal; being able to glide over flat sections, pump, float and turn.

This requires a surf craft that’s light, with lots of float.

Which is why lots of surfers will opt for Epoxy's in waves in this bracket.

MEDIUM WAVES: 3-6FT

As the waves increase in size, so too does their power - making speed generation and maintenance less of an issue.

At this size, things like drive, how your board holds through turns, and how much you can lay it on rail become more important.

These things generally require a little more weight in the board, or the ability for the board to cut through the water rather than float above it - all characteristics of a PU board.

Plus, this is where that flex comes in too, adding extra spring and zip through turns.

BIG WAVES: 6FT+

Bigger waves require a different approach altogether.

If you’re a WCT surfer you’re going to be attacking these waves just like us normal surfers attack a head high wave.

But for us norms, we usually surf these bigger waves much differently.

Generally speaking we’ll take much straighter lines, and surf much more conservatively than normal, which makes things like ‘hold’ and ‘drive’ more important.

At this size too, generally a little extra weight is welcomed as it helps the board to cut through any chop on the waves, and slice into the water as you turn.

As such, PU is generally the preferred option at this size.

LAST MINUTE DEALS

BOAT CHARTERS

SURF RETREATS

SURF CAMPS

Sign up for our weekly 'last minute' deal digest - discounted surf travel: Boat Charters, Retreats, and Surf Camps. Curated, and delivered directly to your inbox.

WHAT SHOULD I CHOOSE?

If you're a beginner to intermediate surfer, the performance nuances between construction type will largely go unfelt, with the differences being so subtle.

Furthermore, the type of waves you'll be surfing day to day will rarely get over the 4-5ft bracket.

The main things for you to consider at this level will be price, weight, and durability, which can make Epoxy a good choice.

If you're an intermediate or advanced surfer you have a few more things to consider:

What size waves do you normally surf?

What type of surfing do you like to do: Traditional or Progressive?

Will you have more than one surfboard?

Surfers at this level will tend to have a quiver of boards designed for specific wave types.

They'll generally choose Epoxy for small wave grovel boards, PU for high performance waves, and PU for bigger waves.

WRAPPING IT UP

Above and beyond everything that's written in this article is personal preference, and there's no right or wrong.

Take Kai Lenny for example, he chooses to ride Epoxy in the biggest waves in the world, and you'll also see countless WCT surfers ridding PU boards in waist-high waves too.

So ultimately it all depends on the individual.

For my two cents, if you're going with a one-board quiver, get yourself an Epoxy as it'll last longer (if you look after it), and will work well enough in all conditions.

ROWAN CLIFFORD

Rowan is the co-founder of Surf Hub.